Complete sets of equipment for industrial sewage

1 project overview: (in case of coating wastewater)

A lot of waste water will be produced in the production process. Generally speaking, coating wastewater with high concentration of pollutants, complex composition, high water content, high pollution. A new sewage treatment station is planned to be built, and the waste water produced in the coating line is treated. In accordance with the requirements of the environmental protection department, the enterprise wastewater treatment to achieve the "integrated wastewater discharge standard" (8978-1996 GB) level A emission standards.

My company according to the basic situation and discharge requirements of the coating waste water, in line with the principle of less investment, low operation cost, high processing efficiency, to your company reported this design, for your company leadership review.

2 treatment of water

According to the relevant data provided by your company.

3 influent water quality

According to the information provided by your company and the same kind of project sewage water quality, the relevant indicators are as follows

Unit: mg/L (except PH)

project | COD | BOD5 | Suspended matter | oils | phosphate | PH |

numerical value | ≤2000 | ≤500 | ≤500 | ≤50 | ≤20 | 6~9 |

4 water quality

Design water to achieve the "comprehensive wastewater discharge standard" (8978-1996 GB) level A emission standards, the relevant indicators are as follows:

Unit: mg/L (except PH)

project | COD | BOD5 | Suspended matter |

| phosphate | PH | ||

numerical value | ≤50 | ≤10 | ≤10 | ≤1 | ≤0.5 | 6~9 |

5 principles of Technology

Through the analysis of the water quality of coating wastewater and the discussion of the emission requirements, the design of the method of physical chemistry and biochemical technology is adopted to deal with the waste water.

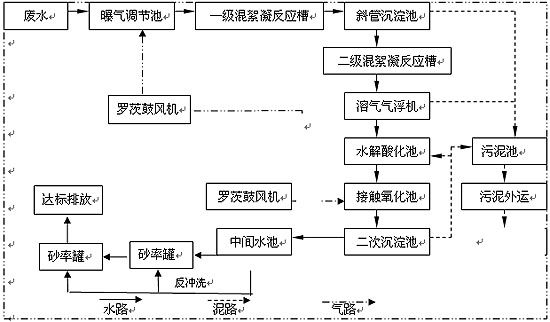

Wastewater is first entered into the aeration regulating tank, regulating the water quantity, the average and the water quality. The waste water is then raised to the first stage coagulation reaction tank through the lifting pump. Mixed flocculation reaction tank is divided into three spaces: the first frame is added into the wastewater of calcium hydroxide, adjusted to pH 10 to 10.5, the wastewater of zinc, nickel, phosphate transformation become solid precipitates; second on the grid to the wastewater with PAC, destruction of colloidal nuances of suspended particles in the water formed stable system, aggregation of suspended particles; the third lattice to the wastewater in PAM, integrated with significant precipitation properties of floc suspended solids in water clusters. After the treatment, the waste water flows into the inclined tube sedimentation tank, and the solid precipitate and the specific gravity of the wastewater are removed.

Inclined tube sedimentation tank effluent into the two mixed flocculation tank, two mixed flocculation tank is also divided into three grids: the first case will waste water PH callback to 8 ~ 7, in favor of the subsequent biochemical unit and flocculation unit treatment efficiency. Second R PAC, so that the water formed flocs. Third R PAM, and then flow into the solid-liquid separation of dissolved air flotation machine.

Flotation machine water flowing into hydrolytic acidification tank, by hydrolysis and acidification, the wastewater in macromolecular organic matter decomposition into small molecular organic matters, will be difficult to degradation of organic matter transformation for easily degradable organic matter, so as to improve the wastewater can be biochemically. Then the waste water flows into the contact oxidation tank, to the waste water in aeration, through the metabolism of microorganisms will waste water pollution in the decomposition, absorption, so that the waste water purification. Contact oxidation pond effluent into the secondary sedimentation tank sludge water separation, biochemistry waterways lift pump rate through the sand tank, a carbon filter tank of water pollutants further adsorption filtration final effluent could meet the discharging standard.

Sedimentation tank sludge, air flotation scum machines are discharged into sludge tank, then through the plate and frame filter press dewatering drying after the reunification of Sinotrans.

6 wastewater treatment process

7 main structures and equipment

7.1 aeration regulating tank

The role of aeration regulation pool is to balance water quality and balance water quantity, which is beneficial to the normal operation of the subsequent treatment system. The aeration regulating tank is provided with a perforated aeration pipe, which can better all the water quality and prevent the sediment from occurring.

7.2 coagulation reaction tank

A total of two sets of mixed flocculation tank, is the main process of the reaction equipment. By adjusting the pH value of wastewater, adding chemicals to the waste water into the sediment, and then through the flocculation reaction will be condensed into large aggregates of pollutants, to facilitate the subsequent removal of equipment.

7.3 inclined tube sedimentation tank

Inclined tube sedimentation tank to remove the flocculation of the first stage of the formation of the flocculation tank, inclined tube sedimentation using the theory of laminar flow to shorten the residence time, a high degree of processing capacity of the sedimentation tank.

7.4 dissolved air flotation machine

Wastewater enters the aeration zone and fully mixed microbubbles, micro bubble in the rising process will be suspended solids brought to the surface, mud scraper run along the surface of the suspended matter blown to tilt on the metal plate, and then is pushed into the sludge discharge pipe groove, through the sludge discharge pipe groove into sludge collector. Flotation machine can be used to remove a variety of industrial and municipal sewage in the suspended solids, grease and jelly, resistance to shock loading, over 90% removal efficiency.

7.5 hydrolysis acidification pool (using the original)

The hydrolysis acidification can decompose the organic matter in the waste water into small molecules, which can be converted into the organic matter which is easy to be degraded, and the biodegradability of the wastewater can be improved.

7.6 contact oxidation pool (using the original)

Decomposition and absorption of pollutants in waste water by means of microbial metabolism.

7.7 sedimentation tank (using the original)

Removal of suspended solids by precipitation.

7.8 sludge pond (using the original)

Storage sedimentation tank, air flotation machine, two settling tank sludge.

7.9 intermediate pool

The function of the intermediate water tank is to store the biochemical sewage, and the inner is provided with a lifting pump to facilitate subsequent filtering processing.

7.10 filter tank

The filter tank in this project is two, respectively, sand filter, carbon filter tank. The role of the biochemical treatment of nearly half of the water adsorption, filtration so that the sewage discharge standards.

7.11 equipment room

The main equipment in place frame filter, blower, electric control cabinet etc..

Complete sets of equipment for industrial sewage 本文被閱讀 1196 次