Slaughter sewage complete set of equipment

1 project overview

1 sources of waste water

Sources of wastewater in the workshop, including (1) prior to slaughter cattle washing wastewater; (2) hot hair, washing carcass wastewater; (3) cleaning visceral wastewater; (4) wash the floor of the workshop, equipment wastewater; (5) washing wastewater pens; (6) the processing of meat products in the waste water. The most serious waste water in the process of slaughter is the most serious blood pollution in the process of slaughter, which is usually released in the process of recovery and utilization, which can reduce the load and increase the income.

2 project overview

The slaughter process will produce a certain amount of waste water, waste water mainly from the slaughter after cleaning, disintegration, cleaning and washing the ground and the ground and rabbit feces waste water and other waste water. Wastewater contains large amounts of organic matter, the main ingredients are: animal feces, blood, animal offal debris, animal hair, broken flesh and oil and other organic matter, belonging to the high concentration organic wastewater. The waste water was brown and red, with a strong fishy smell. Fat, protein and other substances in the wastewater without any treatment, directly discharged into the water body, the surrounding water caused serious eutrophication, serious damage to the self purification capacity of water bodies, caused by the black water has become smelly, the impact of the environment and agricultural irrigation. Slaughter plants to normal production and sustainable development, protect the surrounding water environment, attach great importance to the problem of environmental pollution by wastewater, determined to wastewater on governance, and Shandong Mei Yang environmental protection technology Co., Ltd. Co., Ltd. commissioned management plan. In the understanding of the project basic situation and with reference to the fundamental nature of similar wastewater, according to the requirement of the slaughter plant properties of wastewater and emissions, from reducing wastewater treatment project cost and operating cost of by advanced wastewater treatment technology and equipment, and draws up the the treatment scheme file, for consideration by the enterprise and leaders of relevant departments.

2, design water quantity, water quality:

Water quality: as a result of the party did not provide water quality data, with reference to the same industry wastewater quality characteristics as a reference, to determine the design of wastewater quality is as follows:

Table 1 wastewater quality (mg/l)

CODcr | BOD | SS | NH3-N | PH | Grease | totalP | Coli group |

2000-3000 | 1000-1500 | 900-1500 | 150-200 | 7-8 | 300 | 18 | 3.6x106個/100ml |

CODcr | BOD | SS | NH3-N | PH | Grease | chroma | Coli group |

500 | 300 | 400 | _ | 6-8.5 | 60 | _ | _ |

3 design principles of sewage treatment system

Conscientiously implement the national guidelines and policies on environmental protection, so that the design in line with the relevant national laws and regulations, norms, standards.

Considering the characteristics of wastewater quality and quantity of water, the selection of process flow technology is advanced, reliable, economical and reasonable, and the operation is flexible and safe.

Sewage treatment system layout to compact, reduce the area and investment.

Proper disposal of sewage sludge and other gate residues, sediment, to avoid the two pollution.

Automatic control of sewage treatment process, and strive to manage convenient, safe and reliable, economical and practical.

Elevation layout should be as far as possible the use of three-dimensional layout, the full use of underground space. Layout to be compact, to save land.

Designed in strict accordance with the definition of the applicable conditions, the actual situation of the project requirements.

4, sewage treatment system

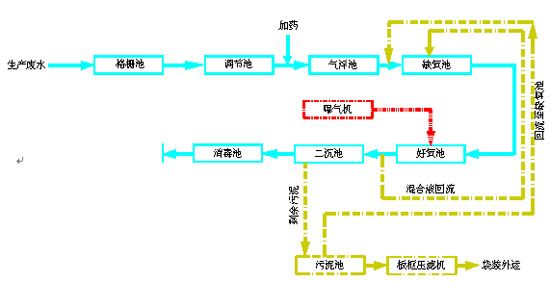

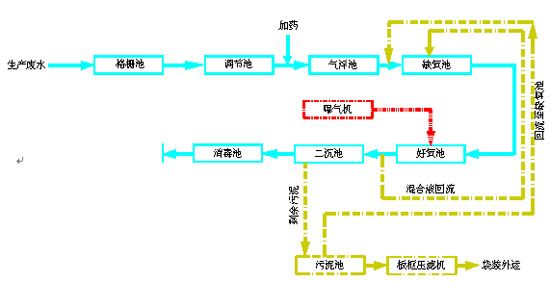

Process flow chart

5 process introduction

Production sewage gravity grille pool in the grille continues in addition to the major pollutants in waste water, such as fragments, broken skin, and other objects to prevent blockage and corrosion pump. The sewage is flowing through the grid to the regulating tank, and the sewage is fully mixed in the regulating tank, so that the water quality and quantity are balanced. Sewage after the regulation pool to the pump before dosing to sewage lifting to the flotation tank and in dissolved gas and water, solid-liquid separation, the vast majority of oil, suspended solids and some of the organic pollutants removal. If too much grease, into the biological treatment system, will affect the effectiveness of biological treatment.

Sewage in the air floating pond after gravity to the anoxic tank, anoxic tank effect, on the one hand can decompose organic pollutants most complex polymer material, improve sewage biochemical coefficient. Sewage stays in the anoxic tank, those difficult biochemical macromolecule organic matter most is decomposed into low molecular easy biodegradability of organic matter and some easy biodegradability of organic compounds in under the action of microorganisms was eventually transformed into water, inorganic chemicals and microbial sludge in sewage removal. Anaerobic the sewage in the refractory organics and hair color groups disintegration, replaced or cracking (degradation), so as to reduce the water color, improve the wastewater biodegradability, even can not directly reduce the water color, due to the molecular structure or chromophore has changed, the likely to be degradation and decolorization under aerobic conditions. On the other hand, there are a large number of denitrification bacteria in the anoxic tank, which can be converted to nitrogen by nitrate and nitrite under anoxic condition.

Anoxic tank flow into activated sludge tank. Under the aeration of aeration, aerobic microorganisms can decompose organic substances into inorganic substances such as CO2 and water, or the synthesis of their own needs, and the metabolism. Most of the organic pollutants in wastewater can be removed by aerobic biochemical treatment. Aerobic tank mixed liquor reflux pump to the activated sludge tank water inlet, improve the sewage treatment effect; processing flow into the secondary sedimentation tank, natural mud water separation; Shen in the sludge bucket in the sludge by sludge pumping returned to the anoxic pool to digest, excess sludge pump delivery to discharge sludge tank to be processed.

6, the processing unit.

6.1 grid pool

Sewage flows through the mechanical grid, removing most of the small and medium sized suspended solids.

6.2 regulating pool

The sewage enters the regulating pond to regulate the water quality and quantity, and ensure the stable and normal operation of the subsequent treatment system.

6.3 air floatation tank

Through to the waste water into the size of the bubbles, wastewater of hydrophobic contaminants particles adsorbed on the bubble, with bubbles to the surface and form contains pollutants foam layer, collected foam layer to remove contaminants.

6.4 anoxic tank

Improving biodegradability of wastewater.

6.5 activated sludge tank

Under the action of the decomposition and synthesis of aerobic microorganism, the organic pollutant is converted to CO2 and water, and the dissolved oxygen is controlled above 2mg/l.

Two 6.6 settling tank

Slurry separation, removal of activated sludge and suspended solids, etc..

6.7 sludge tank

The sludge generated by the regulating pool is driven into the sludge pond, and the sludge generated by the two sedimentation tank is driven by gravity to flow into the sludge pond. Then sludge pump will be sludge tank part of the return sludge to the anaerobic pool and activated sludge pool, sludge with screw pumps into the filter press (filtrate return to adjust pool), and the mud cake Sinotrans.

6.8 disinfection pool

With ultraviolet disinfection, removal of E. coli group.

6.9 equipment room

The built-in equipment: screw pump, sludge pump, filter frame, blower etc..

6.10 electric control room

The built-in equipment: electric control cabinet, laboratory.

Slaughter sewage complete set of equipment 本文被閱讀 1148 次